Your success is our success.

InSource Solutions simplifies success for industrial environments by transforming manufacturing with digitization solutions and services that align industrial operations with business outcomes. We provide solutions and services that help our clients compete globally, and we do it because we are passionate about manufacturing.

Schedule a Free Consultation

Solutions that help you meet the challenge

Unified Engineering Solutions

The Ultimate Digital Twin. UDE solutions deliver data-centric single source truth for engineering information allowing you to design, maintain and operate in compliance with company standards.

Visualization & Supervisory Control

Keep it under control. SCADA Solutions gather data essential to your operations. Simplified context empowers users to visualize, optimize and act addressing abnormal situations before they impact operations.

Workforce Optimization

Today’s modern environment has created new knowledge and skill requirements within the workplace. The workforce optimization process is an integral part of the supply chain that drives a manufacturing company’s…

Manufacturing Execution Systems

AVEVA’s unique Model-Driven MES approach combines the traditional benefits of a manufacturing execution system with modern digital workflow management technology to bring people, organisations and processes together for increased efficiency as well as for capturing work processes and operational procedures in digital workflows and related user experience configurations (models).

Asset Performance Management

Maintain and optimize your asset investment. APM Solutions minimize the whole-life cost, including the operation, maintenance and replacement or disposal of each asset, including energy efficiency.

InSource X0 Solutions™

InSource Solutions is revolutionizing the way data is collected, stored, utilized and maintained with InSource X0 Solutions™. InSource X0 Solutions™ pairs AVEVA world-class software offerings with InSource’s best-in-class services. Our data solutions…

Technology services geared to your operations.

Digital Transformation Roadmap

A successful digital overhaul of plant operations goes beyond just technology.

InSource InSider

InSource InSider solutions offer a wide range of tools, training programs and expert support.

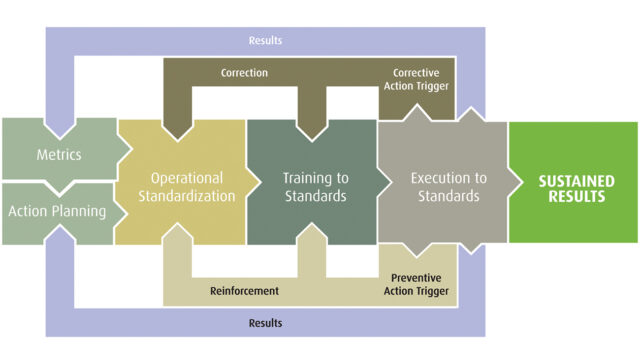

Organizational Change Mgmt

Every organization follows a cadence of reviews, reporting, and communication interaction activities

Self-Paced Training

Go beyond the traditional classroom and even instructor-led online classes.

Management Consulting

Every solution needs to be incorporated into daily routines if we expect real success.

Get your business in sync

Digital solutions deliver transformational results.